Aerospace and Defence has unique challenges, from designing and manufacturing small high volume components through to the static build of large complex structures for use on land, air and sea. We have supplied simulation solutions to some of the largest aerospace and defence contractors in the world to help them design and manufacture better products more safely and efficiently.

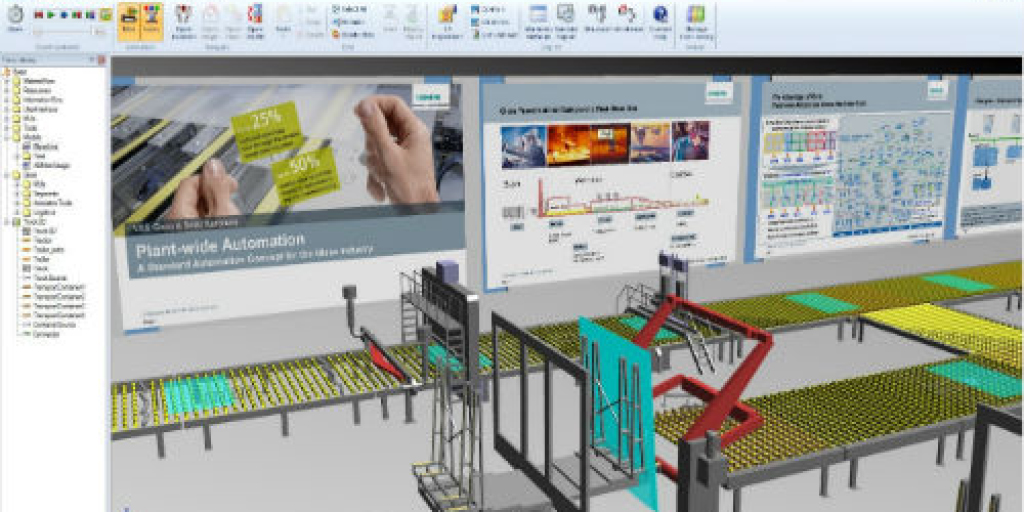

The Tecnomatix suite of Siemens Digital Industries Software products can be applied within the Aerospace and Defence Industry to provide solutions for a wide variety of problems relating to manufacturing, product design and supply chain logistics.

The Siemens Tecnomatix products that have added value to our Aerospace and Defence customers include: