Tecnomatix Variation Analysis is a powerful geometric dimensioning and tolerancing (GD&T) tool used for the simulation of manufacturing and assembly processes in a 3D environment to predict the amounts and causes of variation in products, helping to improve manufacturing quality whilst saving on time and cost.

Tecnomatix Variation Analysis supports manufacturers to virtually validate tolerances to guarantee that parts fit, function and are totally interchangeable early in the product development process before physical parts have even been made, helping to reduce the negative impact of variation on product quality.

Tecnomatix Variation Analysis has the best-in-class GD&T simulation engine and assembly solvers. It’s easy to use and supports multi-CAD through the JT file format which significantly reduces memory requirements, speeding up the response of your systems.

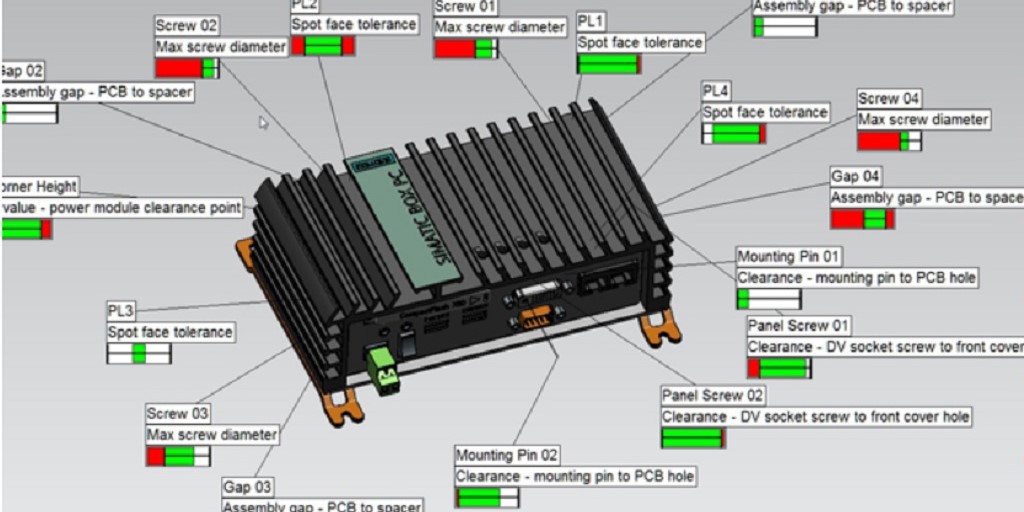

A 3D model of a product in Tecnomatix Variation Analysis enables design teams to