Optimising warehouse layout design is a key concern for many. Specifically, retailers based in clothing, groceries and other products must contend with several issues, including retail distribution and cross-docking. Equally, manufacturing and logistics organisations will face warehouse analysis problems such as how to minimise walking time, eliminate double handling, reduce material movements or maximise space utilisation. For example: “What is the cost of each move?” is a common requirement.

Our Experience, Expertise and Warehouse Design Software are best placed to create intelligent warehouse layout models and help optimise warehouse design. Money invested up front in warehouse analysis can be recouped many times during subsequent implementation and use.

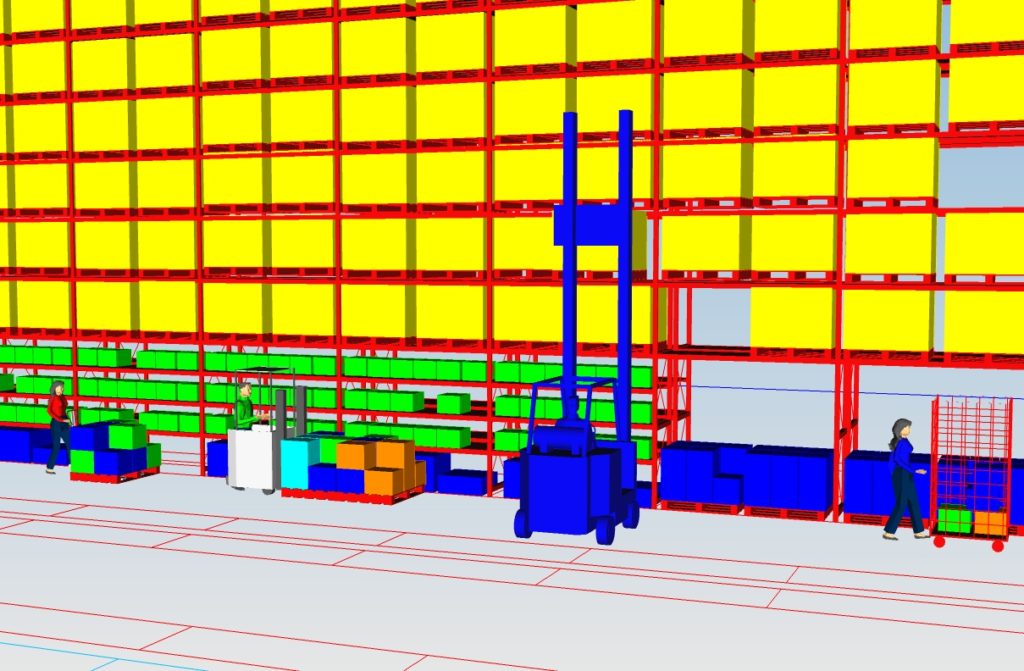

We can quickly create detailed, intelligent warehouse planning models, easily import architectural and equipment models (AutoCAD, NX, JT, Solid Edge, Parasolid, etc.) to produce both plans and models in simultaneous 2D and 3D. Our detailed warehouse design visualisation can be used to create 3D walkthrough movies and both 2D/3D interfaces to Discrete Event Simulation.

Our Operational Material Flow Analysis enables us to optimise your warehouse layout based on material flow distances, MHE utilisation, traffic congestion and cost. We can analyse and validate operator walk-paths, build tow-tug routes based upon material requirements, design packing strategies for storage areas and transport vehicles as well as provide a data interface to Dynamic Simulation

The benefits of using our Experience, Expertise and Warehouse Design Software are: