‘We would have been less inclined to offer the service to our customers without the depth of training and ongoing support from the team at Simsol. The peace of mind of being able to resolve any software or application queries with expert help from Simsol, backed up by Siemens meant we could deliver the project with precision and confidence to our automotive client’

Martin Hibbert, Director, Simulo.

Simulo has been operating as an engineering services provider, specialising in robotic simulations for the automotive, aerospace and rail industry for over twenty years. Simulo was approached by a luxury car manufacturer with a passion for delivering quality experience on a line builder project, working collaboratively with the OEM (original equipment manufacturer) and suppliers across the supply chain. The requirement for the final virtual commissioning work was to use Process Simulate, the automotive industry standard software from Siemens Digital Industries. This meant migrating work created in the well-established Robcad software used in the earlier design and simulation stages of the project. Simulo Director, Martin, came to Simsol for support in using Process Simulate to deliver the automotive project.

Provide engineering services for an automotive line builder project with a tier one supplier. Working collaboratively with different specialists across the supply chain to deliver virtual commissioning using Process Simulate software.

The project was delivered following onsite training from the specialist simulation engineer team at Simsol. Learnings on using Process Simulate software were reinforced through ongoing project support, including: best practise approaches applied to the project, troubleshooting and diagnosing unexpected simulation behaviours, and providing drafts for elements of the simulation.

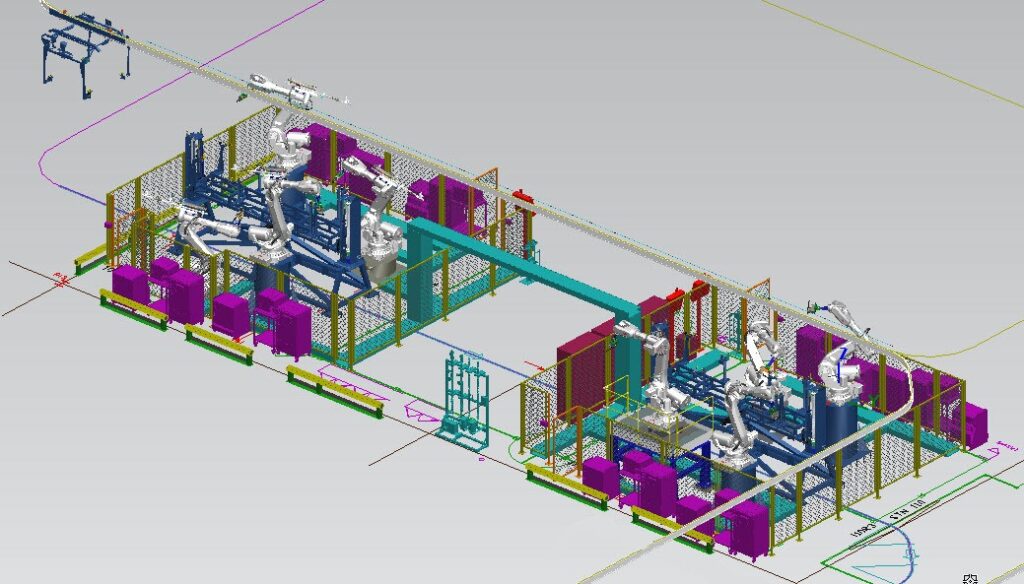

New line simulation created in Process Simulate to virtually commission all elements, covering 2 stations and 8 robots.

Feedback from the automotive client focussed on the rigour of the approach to virtual commissioning, covering every aspect of validating the PLC code in a robust way: ‘the simulation developed to react exactly as the machine on the factory floor does, providing precision and efficiency’.

With the support of Simsol, Simulo was able to smoothly enter into offering virtual commissioning as a service, initially benefitting from the flexibility of a subscription model from Siemens. After the monthly commitment for the project, Simulo went on to invest in multiple licenses to deliver further virtual commissioning projects for the automotive manufacturer and more clients.