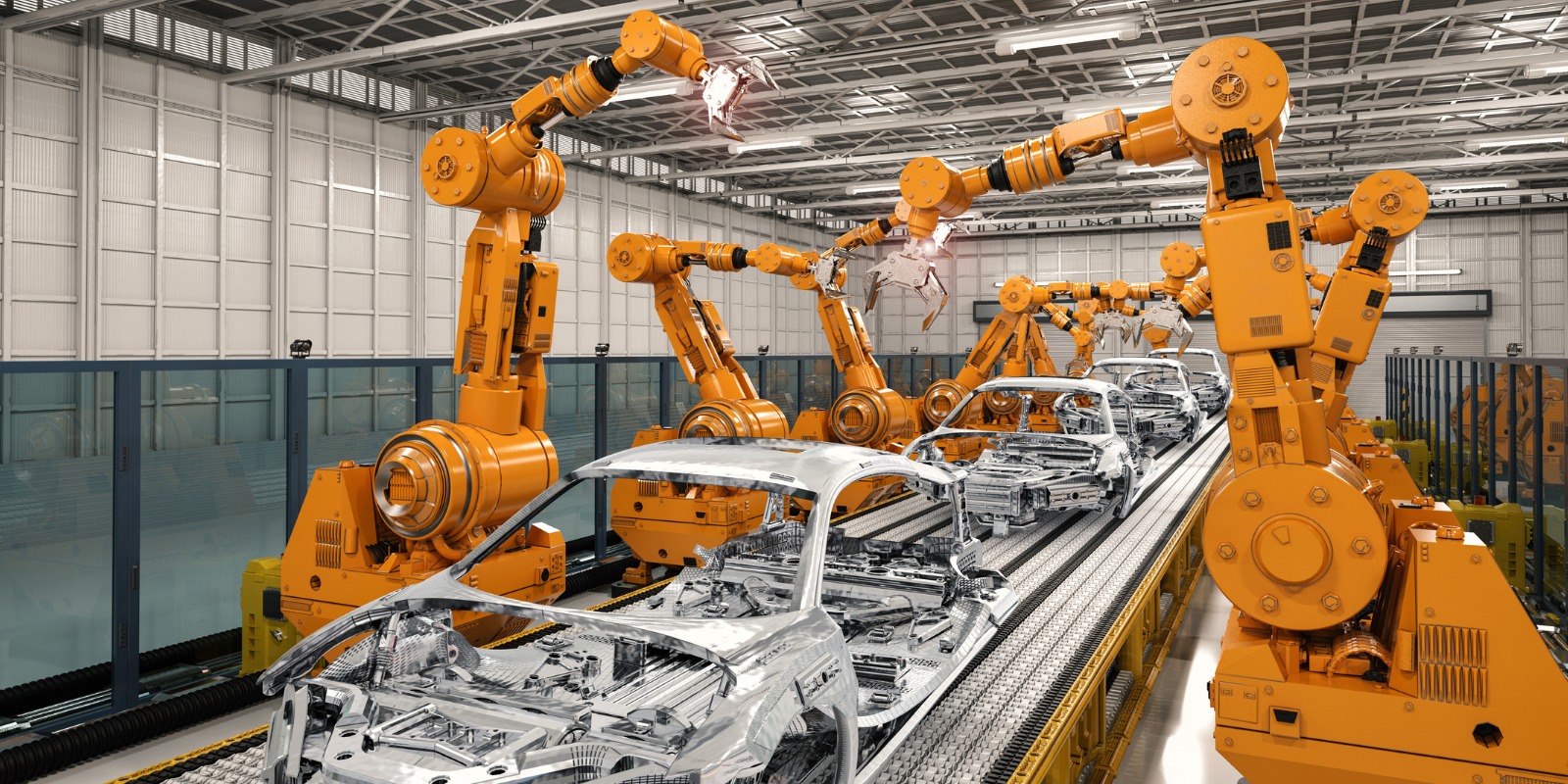

The automotive industry is often cited as one of the most efficient and lean manufacturing sectors. For nearly 20 years Simulation Solutions have supplied and supported simulation technologies that meet the requirements for faster development, leaner supply chains and safer factories.

The Tecnomatix suite of Siemens Digital Industries Software products can be applied within the Automotive Industry to provide solutions for a wide variety of problems relating to manufacturing, product design and supply chain logistics.

The Siemens Tecnomatix products that have added value to our automotive customers businesses include: